Call Trinity: (800) 456-7473

Steel Cutting & Custom Services

In addition to quality American-made steel, Trinity Products provides laser cutting, plasma cutting, and custom fabrication capabilities to get your material application ready. Our strategically located facilities deliver the capacity and speed you need to keep projects on schedule.

Steel Processing & Custom Services

Trinity Products goes beyond steel distribution with comprehensive value-added services that keep your projects moving. Whether you need precision-cut components, custom parts, or expedited services, our advanced capabilities deliver results you can count on.

Reliable Capacity

When your fabrication resources are at capacity, we provide the overflow support you need. With multiple facilities and advanced equipment, you can keep your projects on schedule even during high-demand periods.

Robust Inventory

With abundant stock of steel grades and reliable sources for specialized materials such as military and marine grades, Trinity has the steel needed for your parts within easy reach.

Specification Compliance

From straightforward cuts to complex geometries, we work from your drawings and specifications to deliver parts that meet your exact requirements. Our CNC-controlled equipment handles intricate designs with consistent results.

Shorter Lead Times

Strategically located facilities mean faster delivery. We provide timely quotes, quickly process your orders, and deliver material to you when you need it.

Laser Cutting Services

Our state-of-the-art laser cutting capabilities handle steel up to 1.5 inches thick with clean, precise cuts. Using CNC-controlled laser systems, we can cut complex geometries and intricate parts from your drawings and specifications. Whether you need simple rectangular cuts or detailed custom shapes, our laser cutting services deliver consistent results for components as small as 3/16 of an inch.

Key Applications:

- Custom brackets and mounting plates

- Precision-cut structural components

- Complex geometric shapes

- Small batch and prototype parts

Plasma & Oxy-Fuel Cutting

For thicker materials up to 8 inches, our plasma and oxy-fuel cutting capabilities provide power for heavy-duty applications. Our multi-torch burn tables can handle large-scale projects and thick plate cutting while maintaining the dimensional accuracy your specifications require. This process is ideal for structural components, heavy fabrication work, and high-volume cutting operations.

Key Specifications:

- Material thickness: Up to 8 inches

- Large table capacity for oversized parts

- Multi-torch capability for high-volume runs

- Suitable for all steel grades and alloys

Custom Steel Fabrication

Beyond cutting, Trinity Products offers comprehensive custom fabrication capabilities to transform raw steel into application-ready components. Our AISC-certified facilities combine cutting, welding, drilling, and forming operations to create the custom parts your projects require. From simple assemblies to complex structural components, we have the equipment and expertise to bring your designs to life.

Fabrication Services Include:

- Hole drilling and machining

- Bending and forming

- Surface preparation and finishing

Welding Capabilities

Trinity Products employs approximately 70 fully qualified welders certified to AWS D1.1 requirements, ensuring the highest standards of structural welding quality. Our welders are primarily trained in MIG welding and submerged arc welding (SAW) for specialized applications, including spiral-welded pipe production. All welding operations are conducted under Welding Procedure Specifications (WPS) with testing supervised by certified Level II NDT Inspectors.

Welding Capabilities:

- 70 AWS D1.1 certified welders

- MIG welding (FCAW-G process)

- Submerged arc welding (SAW)

- Spiral-welded pipe production

- Comprehensive weld testing and quality control

Why Choose Trinity Products?

Established & Employee-Owned

Founded in 1979, Trinity Products is a 100% employee-owned enterprise with nearly five decades of steel industry experience. Our 245+ employee-owners are invested in delivering quality results for every project.

Proven Track Record

From major infrastructure projects to custom industrial applications, Trinity Products has successfully delivered value-added services for customers across multiple industries. Our experience spans transit systems, construction, and industrial applications.

Quality Assurance

Our AISC-certified fabrication facilities and comprehensive quality control processes ensure every part meets your specifications. We maintain rigorous standards throughout our cutting and fabrication operations.

"Everything turned out great and this is a good product to replace the old way."

ERIC W. DICKHAUT | COUNTRYMARK

"After we got the hang of it, we were putting these pipes together easily. I’m never welding large OD pipe again unless I have to!"

JEFF OLSON | MIDWEST BORINGS

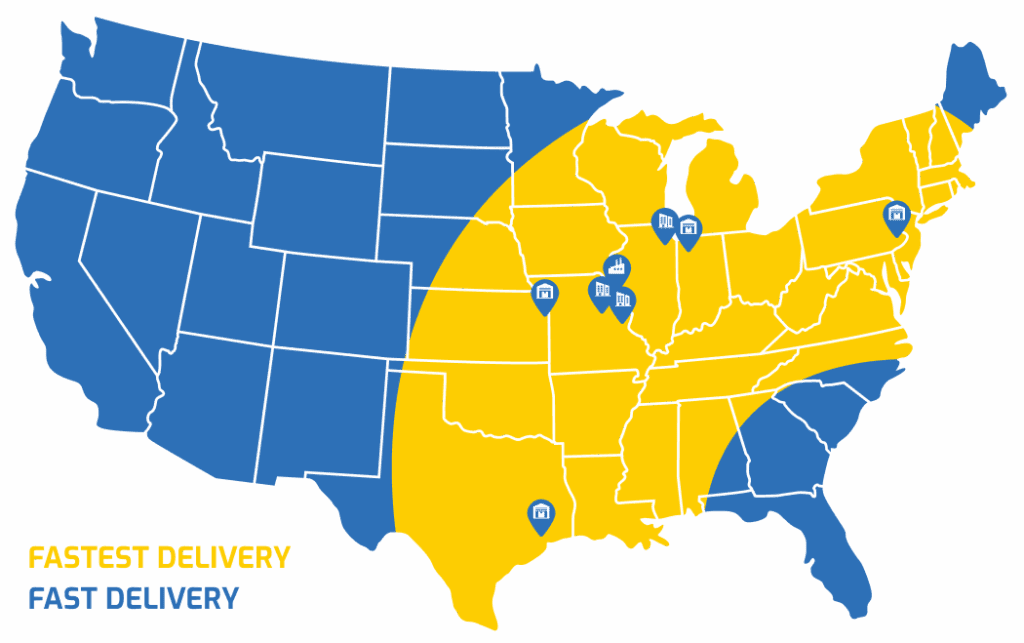

Nationwide Service

With six locations strategically positioned throughout the United States, Trinity Products offers comprehensive coverage and fast delivery across the nation. Our central location advantage means shorter shipping distances, reduced transportation costs, and faster project completion times. Whether your project is local or nationwide, we have the geographic reach to support your needs efficiently.

- Optimal shipping to major markets

- Distributed capacity and redundancy

- Nationwide reach

- Efficient transportation and delivery coordination

Frequently Asked Questions

What size parts can you fabricate?

With our oxy fuel/plasma cutting capabilities, we can produce parts in sizes ranging from 18-gauge up to 120” x 480” (10’ x 40’). Our laser cutting tables allow us to work with parts up to 120” x 1,080” (10’ x 90’). Our equipment capabilities vary by location, so contact us with your specific size requirements and we’ll match you with the right facility for your project.

Can you provide materials that meet M&M USA and DFARS compliance requirements?

Yes, Trinity Products can supply materials that are melted and manufactured in the USA (M&M USA) when required for Department of Transportation work and other government projects. We also maintain DFARS (Defense Federal Acquisition Regulation Supplement) compliant materials and specialty grades including military and marine specifications. Connect with a Trinity expert to discuss your specific compliance requirements and material sourcing needs.

What file formats do you accept for custom fabrication?

We work with standard CAD file formats, including DXF/DWG files. Our engineering team can review your drawings and specifications to ensure optimal cutting paths and material utilization.

How do your services complement my existing fabrication resources?

Trinity Products is designed to work as an extension of your team, providing extra capacity during peak periods or production services for specific projects. We complement your existing relationships and capabilities with the production capacity you need to win big projects and meet your customers’ demands.

What materials can you process?

We work with all standard steel grades, including mild steel, high-strength steels, and military and marine alloys. Contact us to discuss specific material requirements for your project.

How quickly can you turn around cutting and fabrication projects?

As fast as possible. We’re faster than Amazon in many cases when it comes to raw materials, and our lead times on cut parts aren’t far behind. Our multiple locations provide flexibility to expedite urgent projects when needed.

Do you provide material sourcing?

Yes, Trinity Products provides both raw materials and processing services, offering a complete solution for your steel needs.

Ready to Add Trinity Products to Your Supplier Network?

Whether you need immediate capacity for an urgent project or want to establish a relationship for future value-added services, Trinity Products is ready to support your steel cutting and fabrication requirements. Get started with a quote today or download our information packet to add us to your RFQ process.

Get Started

"*" indicates required fields