Call Trinity: (800) 456-7473

Pipe School

Continuing Education

12 PDH (Professional Development Hours) for all who participate!

Past Topics: Steel Making, Steel Casting, Steel Rolling, Metallurgy, Welding Specifications & Types, Pipe Making, Effects of Yield & Tensile on Piling, Tensile Point, Coatings, Logistics, Scrap, Trinity Manufacturing Plant Tour, Omega Beam Development.

Pipe School 2026: Sept. 16-18, 2026

Featured Speakers

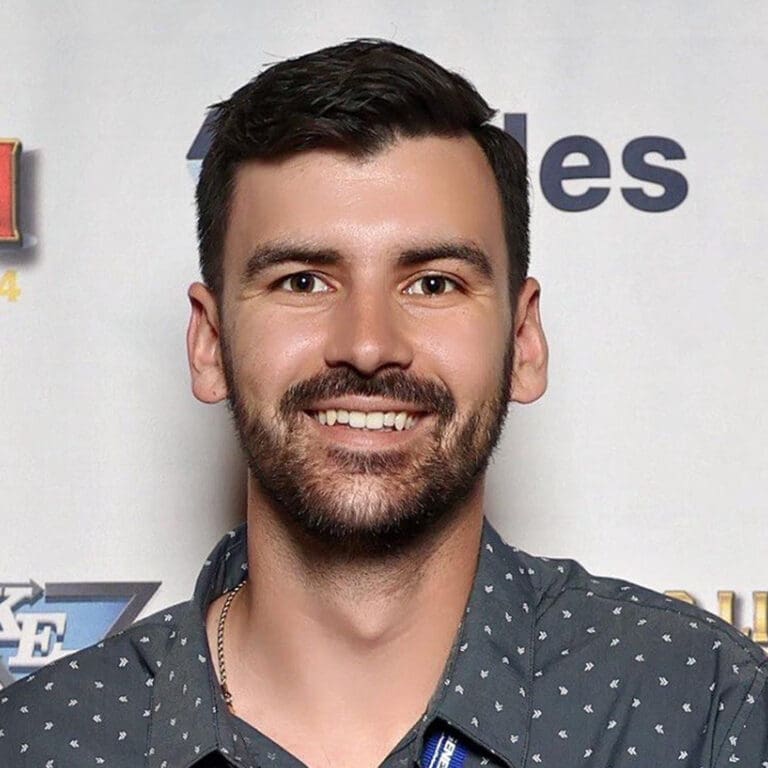

Charles Lamb

CEO & Executive Board Member, EEW AOS

Charles Lamb is the CEO and Executive Board Member of EEW AOS, a leading manufacturer of offshore windmill monopile structures. With over 25 years of operational leadership experience in the metals and manufacturing industries, Charles has held executive roles at both private and publicly traded companies, guiding businesses through rapid growth, transformation, and IPO preparation.

At EEW AOS, Charles is responsible for building North America’s first monopile manufacturing facility, securing a domestic supply chain, and leading the company’s expansion in the renewable energy sector. His previous roles include Senior Director of Operations at Amentum and Director of Operations at Trinity Products, where he led initiatives that significantly improved throughput, reduced costs, and expanded market share.

Charles is a subject matter expert in energy transmission pipe manufacturing and has spoken at more than 300 symposiums across 121 countries. He holds a degree in Automated Manufacturing and is certified in Six Sigma, ISO 9001 auditing, and plant maintenance. Charles lives in the Chicago area with his wife, has four children and four grandchildren, and volunteers with several industry and community organizations.

Session Topic

Pipe Making: Longitudinal vs Helical Welded Pipe & Pipe Tolerances

This session will provide a comprehensive exploration of welding techniques and troubleshooting methods. Participants will gain hands-on insights into key welding approaches, learning how to identify and address common issues that arise during the process. The session includes a detailed discussion of various welding types and their practical applications. A focus will be placed on recognizing and troubleshooting weld anomalies using macro etches, as well as understanding the crucial difference between defects and indications. In addition, essential inspection techniques will be presented to ensure weld quality and structural integrity throughout a project.

The session will also explore the fundamental differences between helical and longitudinal manufacturing processes for pipe production. Attendees will examine how each method influences pipe strength, dimensional control, fit-up, and cost efficiency. By comparing the two approaches, participants will develop a clear understanding of how manufacturing technique affects application suitability, overall project performance, and budgeting decisions.

Finally, the session will deliver a detailed overview of pipe types and the tolerance standards associated with them. This portion will cover key specifications, including A252 and A139, and will address considerations related to base metal strength. Attendees will also learn about the tools and methods used to measure and verify tolerances, making this an ideal segment for professionals aiming to strengthen their knowledge of pipe specifications and quality control.

Jason Adams

Vice President of Industrial Excellence, Vallourec USA

Jason Adams is the Vice President of Industrial Excellence at Vallourec USA, a global manufacturer of seamless pipe and tube headquartered in France. He brings over 28 years of experience in flat-rolled steel production, having held key roles at companies such as US Steel, NLMK, and Cleveland-Cliffs. Before his current position, Jason spent eight years in the aluminum extrusion industry with Hydro Extrusion NA, LLC.

His areas of expertise include steelmaking, rolling and processing of ferrous and non-ferrous materials, quality, engineering, operations, supply chain management, and lean manufacturing. Jason holds both a B.S. and M.S. in Metallurgical Engineering, is certified in Lean Manufacturing by the Toyota Engineering Corporation, and is currently pursuing a Ph.D. in Business with a focus on Organizational Leadership.

Session Topic

Physical & Process Metallurgy of Carbon Steel

This session provides an essential overview of carbon steel manufacturing, introducing key industry terminology, hot-rolled product types, and relevant specifications. Attendees will gain a foundational understanding of the entire steel value chain—from ironmaking to hot rolling—with a focus on flat-rolled process technology. The session will explore how processing influences material structure and properties, highlighting the role of chemistry and controllable metallurgical factors in achieving desired product outcomes. It will conclude with an overview of the testing methods used to verify product performance and quality.

Amy Francik

Director of Safety, Trinity Products

With over two decades of dedicated experience in occupational health and safety, Amy Francik is a seasoned Safety Professional known for developing, implementing, and managing effective safety programs across diverse industrial environments. Her career reflects a consistent commitment to fostering a proactive safety culture, reducing risk, and ensuring regulatory compliance.

Throughout her career, Amy has led initiatives that resulted in significant reductions in workplace incidents, championed employee engagement in safety processes, and successfully navigated complex OSHA, EPA, and local compliance requirements. Known for a hands-on, collaborative leadership style, Amy excels at training, auditing, incident investigation, and continuous improvement efforts that align safety with operational goals.

Trinity Plant Tour

Before touring Trinity’s state-of-the-art Steel Pipe Mill and Horizontal Boring Mill (HBM), attendees will receive a brief but important safety orientation outlining site protocols, required PPE, and emergency procedures. The guided tour will offer an up-close look at the steel pipe manufacturing process—from raw material to finished product—as well as the precision machining capabilities of the HBM facility. This behind-the-scenes experience highlights Trinity’s commitment to safety, innovation, and quality in heavy steel fabrication.

Trevor Gonterman

Tri-Loc Specialist, Trinity Products

Trevor Gonterman serves as the Tri-Loc Specialist at Trinity Products, where he leads the advancement and strategic growth of Trinity’s innovative mechanical press-fit connection system, Tri-Loc. With over 20 years of experience in the metals industry, Trevor has cultivated a broad and in-depth knowledge base across flat-rolled steel, fabricated components, and specialized pipe and tubular products.

A graduate of Saint Louis University, Trevor has built his career around delivering engineered material solutions to complex infrastructure challenges. Over the past decade, he has concentrated his efforts in the trenchless and underground construction sector, working extensively with leading global equipment manufacturers, engineers, and contractors. His contributions have positioned him as a trusted industry expert and resource across domestic and international markets.

Trevor is widely recognized for his thought leadership in trenchless technology, having authored multiple technical papers and delivered presentations at major industry conferences. His work has helped shape the development of new materials and product applications that support evolving installation methodologies, driving forward the capabilities of trenchless construction.

With a passion for innovation and collaboration, Trevor continues to influence the industry by aligning product development with the needs of owners, specifiers, and builders. His role at Trinity reflects this commitment, as he steers Tri-Loc into new markets and applications, including vertical and European segments, helping to redefine standards in mechanical pipe connection technology.

Session Topic

Tri-Loc: Precision Mechanical Press-Fit Connections for Steel Pipe

Trinity Products has transformed trenchless pipe installation with its Tri-Loc mechanical press-fit connection, proudly manufactured in the USA. Offered in both 3- and 4-tooth profiles, Tri-Loc delivers a tight, secure fit ideal for demanding tunneling applications. Extensive testing confirmed its exceptional performance under high jacking forces. To elevate precision and quality, Trinity invested $9 million in a state-of-the-art Horizontal Boring Mill, enabling connections to be machined directly into the pipe. This results in highly accurate joints with industry-leading tolerances, supported by a certificate of compliance for each piece. In-house manufacturing ensures consistent quality and dependable performance across all projects, while a vertically integrated process slashes production times by 50%. In this session, you’ll discover how Tri-Loc delivers precision, consistency, and efficiency—making it a superior, cost-effective choice for trenchless applications. Trinity’s employee-owners are committed to continuous innovation, ensuring Tri-Loc remains at the forefront of the industry. Join us to learn how this cutting-edge connection can add value to your next project.

Cody Peckham

Vice President of Operations, Mighty River Recycling

Cody has been with Mighty River Recycling full-time for four years. With a background in aerospace engineering and prior experience in defense contracting, he eventually chose to bring his skills into the family business. Since joining the MRR team, Cody has focused on streamlining operations and building a strong partnership with Alton Steel Mill. He leads an operations team of over 25 employees, overseeing the preparation and transportation of recycled materials to ensure customers have the raw resources they need to produce new steel.

Session Topic

Scrap 101

Scrap 101 offers an look at the life cycle of a Trinity Pipe and the critical role scrap metal plays in today’s economy, environment, and your business. We’ll explore how recycled metal serves as a key raw material in steel production and examine the differences between electric arc and blast furnace technologies—and their impact on both the environment and the recycled materials market. The presentation also covers the global commodity market, job creation, and the significant energy savings associated with using scrap metal to produce new steel.

Connor Peckham

Vice President of Sales & Marketing, Mighty River Recycling

Connor has been a full-time member of Mighty River Recycling for six years, building on early experience gained during high school summer breaks with the company. He holds a business degree with a concentration in entrepreneurship, which he has effectively applied to leading a dynamic team of marketing and sales professionals. Connor is dedicated to enhancing customer relationships and supporting the growth of their recycling initiatives. He plays a key role in closing the recycling loop by connecting companies like Trinity with end users of recycled materials, such as Alton Steel.

Session Topic

Scrap 101

Scrap 101 offers an look at the life cycle of a Trinity Pipe and the critical role scrap metal plays in today’s economy, environment, and your business. We’ll explore how recycled metal serves as a key raw material in steel production and examine the differences between electric arc and blast furnace technologies—and their impact on both the environment and the recycled materials market. The presentation also covers the global commodity market, job creation, and the significant energy savings associated with using scrap metal to produce new steel.

Pipe School Registration

Thank you for planning to attend our course. A representative will contact you soon to confirm your reservation.

Pipe School 2025

Pipe School 2024

Pipe School 2023